The food processing industry is modern society’s cornerstone, transforming raw agricultural products into consumable goods. It relies heavily on advanced equipment that automates handling and processing tasks, improves efficiency and consistency, and integrates safety measures to comply with health regulations.

Inflatable seals are one of the key components of this equipment, and Seal Master Corporation has emerged as a pioneer in this domain.

Seal Master Corporation’s Inflatable Seals

Seal Master Corporation, founded in 1974, is a leader in designing and manufacturing high-quality inflatable seals for niche markets, including the food processing industry. We consistently deliver solutions for specialized equipment, guaranteeing the following features.

Superior Structural Integrity

Seal Master Corporation combines advanced manufacturing techniques with meticulous craftsmanship. As such, our inflatable seals deliver superior resilience and flexibility.

We use highly engineered and handcrafted materials, consistently outperforming traditional mechanical alternatives. Our production process utilizes premium-grade rubber compounds that defy the rigors of food processing environments, including extreme temperatures and exposure to various chemicals.

Our inflatable seals are not subject to compression sets, a common issue where seals lose their effectiveness over time. The robust construction withstands thousands of duty cycles without degradation, making our seals a long-lasting solution for food processors. Moreover, our fully molded, reinforced rubber inflatable seals provide consistent pressure along the entire surface, preventing leaks and maintaining the integrity of processing equipment.

FDA-Approved Materials

Our dedication to the food processing industry goes beyond meeting compliance standards. We exemplify our commitment to excellence by using FDA-approved silicone, a robust material enhanced with a specific color additive, resulting in a distinct orange hue. This silicone meets stringent FDA regulations and significantly boosts material strength.

We also take immense pride in our ability to provide custom-engineered solutions, allowing us to tailor products to meet the intricate and diverse needs of the food processing sector. Our approach improves the effectiveness of our inflatable seals and gives every client a solution that fits seamlessly within their operational framework.

Simplified Design

The design of our inflatable seals and associated hardware minimizes the need for close machining or fabrication tolerances. This intentional design philosophy facilitates ease of installation and maintenance, allowing operators to replace seals quickly without compromising consistent performance.

Our seals’ flexibility in design allows for easy integration into existing systems, making them an ideal choice for facilities looking to upgrade their equipment without significant structural alterations. As a result, food processing operations can maintain high productivity levels, reduce downtime, and boost overall operational efficiency.

Our Inflatable Seals in Action

Seal Master Corporation’s reinforced rubber seals are an excellent choice for quality-conscious food processing industry professionals. Establish consistent pressure for pushing, lifting, squeezing, stopping, holding, or sealing objects; our solutions will deliver reliable performance in demanding applications.

- Smokehouse: Our custom-design seals fit the unique shape and size of smokehouse batch ovens, preventing heat from escaping.

- Drum Followers: Our inflatable seals offer a robust barrier against external contaminants for drum transfer and drum follower applications.

- Conveyor Systems: When smooth product transfers are paramount, our inflatable seals excel at efficient conveyor operation.

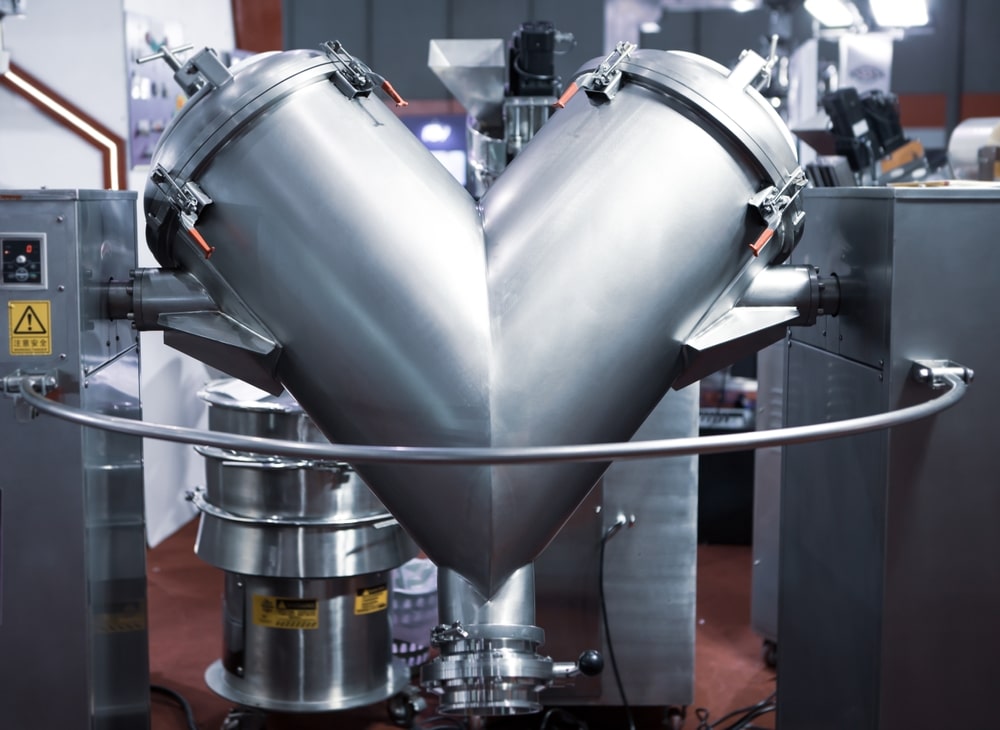

- Agitators: Process viscous materials with our inflatable seals that provide adequate pressure for a secure seal.

- Mixers: Our seals prevent leaks and contamination in mixing processes, ensuring sanitary production.

- Extractors: Prevent unnecessary product loss and maintain internal air pressure in extractor processes.

- Fermentation Tanks: Maintain desired temperature and pressure levels in all your fermentation tanks.

- Refrigerators and Chillers: Keep food products fresh through consistent temperatures in refrigerators and chillers.

- Seasoning Drums: Our seals offer a secure barrier for maintaining the ideal seasoning temperature and moisture levels.

- Roasters: Preserve the delicious flavor and aroma of roasted foods during the cooking process.

- Labeling and Packaging: Our inflatable seals are also suitable for labeling and packaging applications, offering reliable sealing solutions for various products.

- Bottling Machines: Prioritize the safety and quality of bottled products with tight seals during the filling process.

Source High-Quality Food Processing Inflatable Seals From Seal Master

In the demanding environment of the food processing industry, the right components are critical to your equipment’s efficiency, safety, and reliability. Seal Master Corporation’s inflatable seals offer the perfect combination of innovative design, superior materials, and proven performance. When you source your inflatable seals from us, you invest in quality and reliability to keep your operations running.

Request a quote today and discover how Seal Master Corporation can meet your food processing equipment needs with our industry-leading inflatable seals.