FDA-Approved Inflatable Seals for Food Processing Equipment

A leading European food processing manufacturer approached us about needing specialized seals for drum transfer applications.

Industry

Application

Specialized seals for drum transfer and drum follower applications within food processing equipment

Cross Section

G-34, G-35, and G-36

Location

Europe

Industry Background

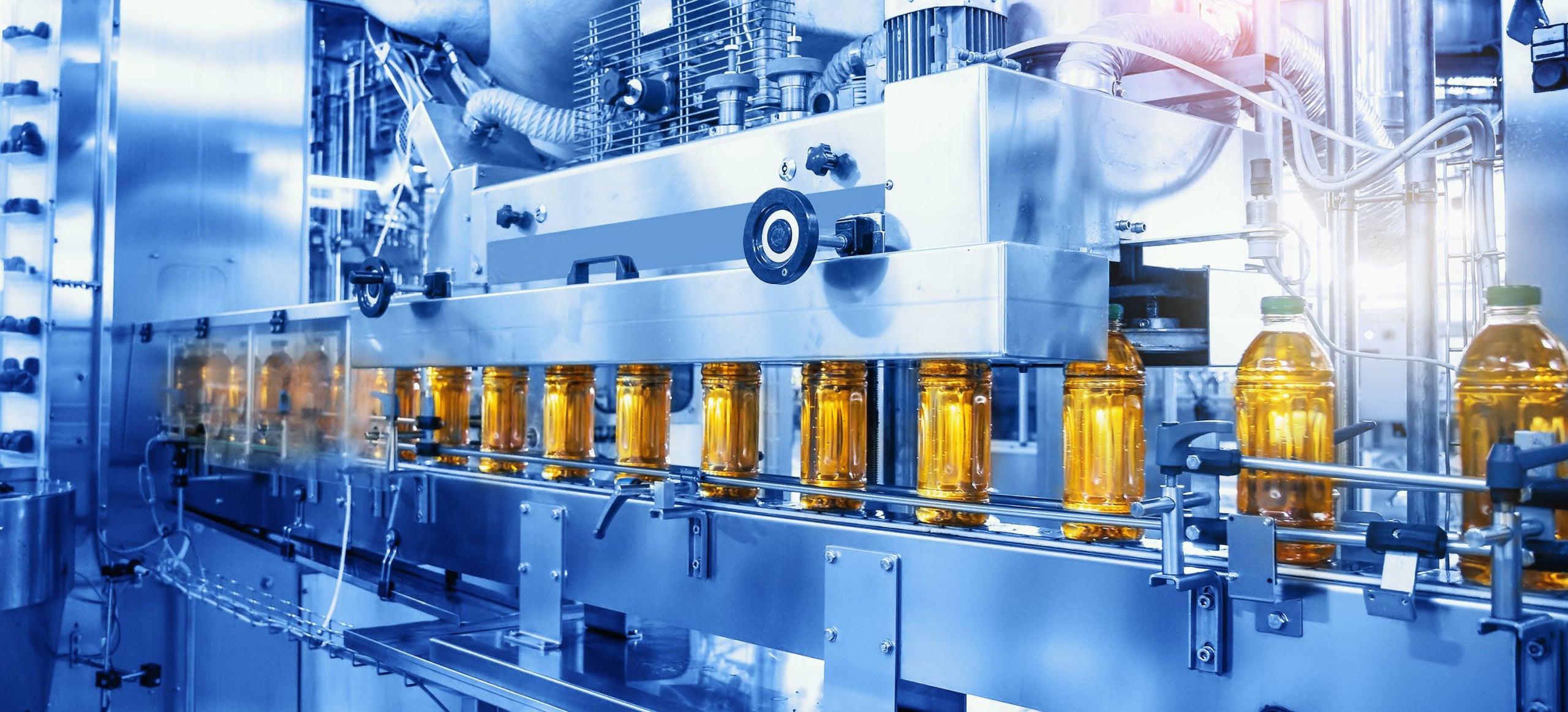

The food processing industry requires the utmost standards of quality and safety, especially when it comes to materials that come into contact with food products. Quality seals play a pivotal role in ensuring the safety and integrity of equipment used.

FDA-approved materials, such those used within Seal Master’s seals, are a testament to the highest level of safety and purity. Given the fluid nature of products like tomato paste or mashed potatoes, the choice of seal material and design becomes paramount.

Project Details

Client: A leading European food processing manufacturer

Requirement: Seals suitable for drum transfer and drum follower applications, made with FDA-approved materials.

Challenge: The client was in search of specialized seals for their drum transfer and drum follower applications within their food processing equipment. These seals play a pivotal role in transferring food products, particularly tomato paste and mashed potatoes. The client required these seals to be FDA-approved, ensuring the highest safety and hygiene standards. Furthermore, the seals needed to be robust enough to handle these viscous food products without compromising their quality. The client's existing solutions were inadequate and did not specifically cater to the unique demands of drum transfer and drum follower operations. This prompted them to seek a custom-engineered solution that would address both the material safety standards and the operational challenges of their processing equipment.

Solution: Seal Master's engineering team, renowned for their custom engineering capabilities, began by understanding the specific needs of the client's processing equipment. They recognized that the seals needed to be robust enough to handle the thick consistency of products, like tomato paste, yet flexible enough to ensure a tight seal to prevent any contamination.

After extensive research, the team identified a unique blend of FDA-approved materials that would be ideal for this application. Several design iterations led to seals suitable for the client's needs. These seals, which can be of various shapes like round, rectangular, or square, are designed for steel drums and other containers. The designs comprise the cross sections Bond-In G-34, Bond-In G-35, and Bond-In G-36. These seals are held in place without a snap-in or fasten-in base attached, ensuring a secure fit.

Furthermore, the team ensured that the seals were easily installable and replaceable, considering the high-frequency usage in food processing environments. The seals were engineered to resist wear and tear, extending their lifespan and reducing maintenance costs.

Outcome: The project's success highlighted Seal Master's commitment to innovation and ability to meet specific customer needs in the demanding food processing industry. The client was particularly impressed with the seal's performance, noting a significant reduction in equipment downtime and an increase in overall processing efficiency.

Need help with your project?

If you’re working on a project of your own and struggling to find the right solution, our engineering team can work with you to solve any problem.