Failure is never an option in radiation-intensive environments such as nuclear power facilities. With this in mind, you need inflatable seals capable of more than just containment.

When you have specific applications and needs for your nuclear facility, your inflatable seals must maintain airtight, contamination-free barriers while exposed to radiation levels that can degrade most elastomers over time. For industries such as nuclear power, medical imaging, and defense, our engineering approach to seals ensures that each one delivers enduring performance in the harshest conditions.

Learn more about how Seal Master Corporation designs inflatable seals for various nuclear applications and environments.

The Importance of Inflatable Seals in High-Radiation Environments

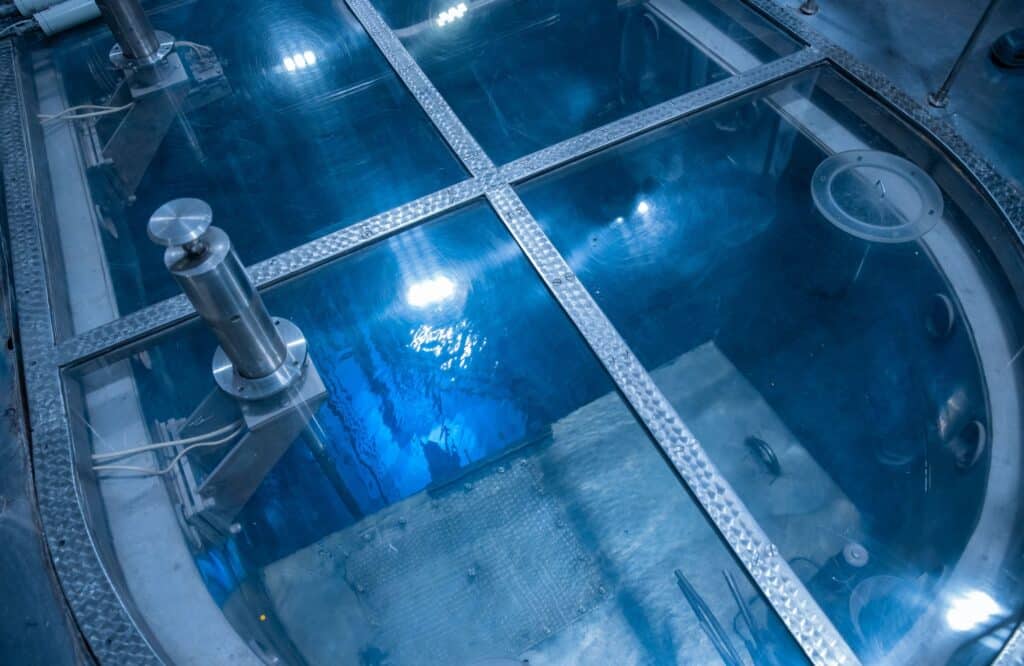

In radiation-intensive systems, inflatable seals fulfill multiple roles that are critical to pressure retention and containment. Used in reactor doors, glove boxes, and containment chambers, they protect both operators and equipment from exposure and contamination.

Radiation can degrade most materials, reducing elasticity and sealing power over time. Inflatable seals counter this through engineered flexibility and controlled expansion, maintaining a reliable barrier even after repeated exposure. Their adaptive design compensates for surface irregularities and pressure changes, ensuring consistent performance where rigid seals would fail.

Built from radiation-resistant elastomers and reinforced fabrics, inflatable seals are indispensable across nuclear, medical, and defense applications, maintaining integrity in environments where failure is not an option.

Material Selection

Reliable inflatable seals for nuclear applications start with the right materials.

Radiation-Resistant Elastomers

Material selection is the cornerstone of seal longevity in radiation applications. Silicone, EPDM, and fluorocarbon (Viton®) are the most common elastomers used, but their behavior under radiation varies.

Silicone offers broad temperature tolerance and flexibility but moderate radiation resistance. EPDM provides excellent ozone and weathering resistance, making it ideal for outdoor or reactor-adjacent uses. Fluorocarbon compounds withstand both radiation and chemical exposure, making them suitable for areas with simultaneous chemical and radiation stress.

For the most extreme cases, we recommend specialty formulations, such as fluorosilicone blends or custom high-fluorine compounds.

These balance radiation resistance with the elasticity needed for inflation and deflation cycles.

Fabric Reinforcement for Structural Integrity

In high-pressure or high-radiation systems, fabric reinforcement enhances dimensional stability and prevents over-expansion. We employ reinforced fabrics like Kevlar®, Nomex®, or fiberglass sheathing to provide the added mechanical strength required for repeated cycling under radiation exposure.

The combination of engineered elastomer and reinforcement ensures seals maintain consistent shape and performance, even after prolonged service.

Engineering for Performance and Safety

Once the right materials are selected, design and engineering follow. During this stage, we ensure that your inflatable seals match your exact specifications and demands.

Precision Groove Design

Radiation environments often involve glove boxes, containment chambers, or reactor doors where tolerance for leakage is near zero. Our engineering process focuses on creating grooves that allow uniform inflation and deflation while ensuring full contact against sealing surfaces.

Proper groove geometry prevents bulging, displacement, and early material fatigue, which are all common failure modes in poorly designed systems.

Retention and Mounting

Depending on the chamber configuration, retention systems may use dovetail, clamped, or adhesive-bonded grooves.

Each design is evaluated for its ability to resist vibration, thermal expansion, and deformation caused by repeated exposure. For removable panels or inspection hatches, we design quick-release retention methods that maintain sealing integrity while simplifying maintenance.

Contamination-Free Operation

In nuclear and clean-energy sectors, contamination control is as vital as sealing itself.

We manufacture inflatable seals in controlled environments and can produce them using materials that meet FDA or Class VI standards when applications require biocompatibility or regulatory compliance.

Each seal is cleaned, inspected, and packaged to minimize particulates or surface residues, ensuring safe integration into containment systems without compromising environmental integrity.

Testing Under Real-World Conditions

Laboratory tests provide a baseline, but only real-world simulation confirms reliability.

We subject seals to controlled radiation exposure, pressure cycles, and temperature extremes to validate performance. Key tests include:

- Leak Integrity Tests: verifying airtight sealing under positive and negative pressure.

- Cycle Life Testing: measuring inflation/deflation endurance up to 500,000 cycles.

- Thermo-Radiation Aging: assessing material elasticity and compression set after prolonged exposure.

By validating every seal under expected service conditions, we eliminate guesswork and shorten the path from prototype to deployment.

Applications Across Radiation-Intensive Industries

Inflatable seals play an essential role in a wide range of radiation-intensive environments, including:

- Nuclear Power Facilities: Seals eliminate gaps in containment doors, pressure vessels, and inspection ports.

- Medical and Research Equipment: Inflatable seals help ensure isolation in PET and CT scanners, glove boxes, and irradiation chambers.

- Defense and Aerospace: The sealing and pressure-maintaining effects of inflatable seals protect systems exposed to radiation during testing, launch, or high-altitude operation.

Design and Deploy for Environmental Extremes With Seal Master Corporation

We combine decades of engineering experience with advanced testing and fabrication capabilities to create seals that deliver lasting protection under extreme conditions.

If your project operates where reliability is non-negotiable, let’s design an inflatable seal that performs exactly as your environment demands.

Contact Seal Master Corporation today to get started!