Fabric Reinforced Inflatable Seals

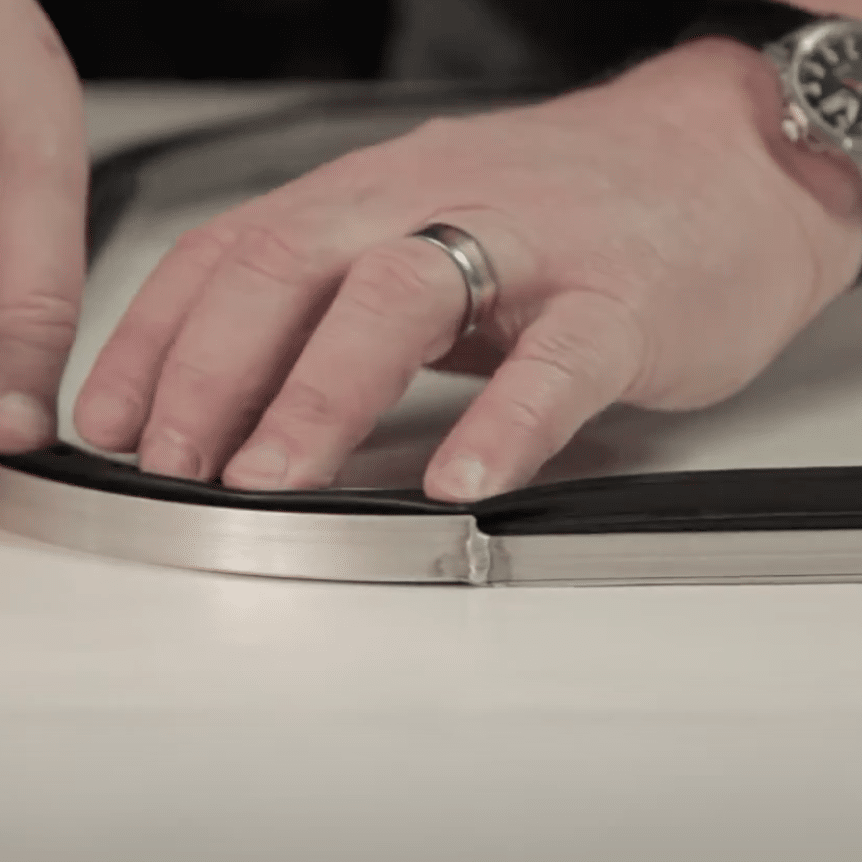

As a leading manufacturer of fabric-reinforced inflatable seals, Seal Master Corporation engineers each profile to meet precise performance specifications.

Fabric-reinforced inflatable seals are engineered for applications where a traditional inflatable seal may not deliver the mechanical strength, stability, or life span required. By integrating high-performance fabrics into the rubber body, these seals provide exceptional resistance to pressure, wear, and deformation, making them ideal for demanding, mission-critical environments.

As a leading manufacturer of custom inflatable seals, Seal Master Corporation engineers each reinforced profile to meet precise performance, space, and environmental specifications.

What Is a Fabric Reinforced Inflatable Seal?

A fabric-reinforced inflatable seal is a rubber seal with internal fabric layers—often made from materials such as nylon, polyester, Kevlar®, Nomex®, or fiberglass—that improve structural strength and long-term durability. When the seal inflates, the reinforcement distributes load evenly, prevents overstretching, and maintains dimensional stability even under high pressure or repeated cycling.

These seals function like standard inflatable seals but are specifically optimized for higher stress, higher pressure, and higher cycle applications.

Why Choose Fabric Reinforced Inflatable Seals?

Higher Mechanical Strength

Fabric layers significantly increase structural integrity, allowing the seal to:

- Withstand higher internal pressures

- Resist extrusion into gaps

- Maintain shape under load or side pressure

- Perform reliably in heavy-duty clamping, sealing, or lifting applications

This upgrade is especially valuable when equipment cycles frequently or when failure could result in downtime or safety concerns.

Superior Wear & Abrasion Resistance

The reinforcement fabric acts as a stabilizing skeleton within the elastomer:

- Reduces localized stress and rubber fatigue

- Minimizes stretching and distortion over long-term use

- Improves resistance to repeated mechanical contact

- Extends service life in dynamic or high-use environments

Applications involving sliding surfaces, compression, or vibration benefit immediately from these durability gains.

Excellent Stability in Harsh Conditions

Fabric reinforcement helps the seal maintain performance and geometry across demanding environments:

- Resist distortion during dynamic movement

- Maintain consistent shape through temperature swings

- Hold up to cleaning agents, chemicals, and industrial exposures

- Preserve integrity under UV, moisture, and abrasive conditions

Common Fabric Reinforcement Materials

Seal Master Corporation offers a wide range of reinforcement fabrics based on application demands:

- Nylon

- Polyester

- Fiberglass

- Kevlar®

- Nomex®

- Specialty woven and non-woven fabrics

These materials can be combined with elastomers from Seal Master Corporation’s material portfolio, including:

- EPDM

- Silicone

- Fluorosilicone

- Natural Rubber

- Nitrile (Buna-N)

- Neoprene

- Conductive or food-grade compounds

- …and many others

Where Fabric Reinforced Inflatable Seals Are Used

Reinforced designs are ideal for applications requiring repeated cycling, heavy loads, or challenging environmental conditions, including:

- Door and hatch seals

- Autoclaves and containment systems

- High-pressure clamping fixtures

- Equipment undergoing constant movement or vibration

- Sealing systems exposed to harsh chemicals or abrasive media

- Industrial automation and high-duty OEM systems

If your application pushes traditional seals to their limits, fabric reinforcement is often the most reliable path to performance and longevity.

Custom Engineered for Your Application

Every reinforced inflatable seal Seal Master Corporation produces is custom-designed. Our engineering team collaborates directly with your designers to determine:

- The right reinforcement fabric

- Optimal elastomer compound

- Seal geometry and profile

- Inflation performance requirements

- Environmental and regulatory considerations

Whether you’re replacing an existing seal or developing a new product, we help you select the right combination of materials and design features to achieve consistent, repeatable performance.

Fabric-Reinforced Inflatable Seal Resources

Free Download:

How to Scope Your Seal

Get valuable insights into the material properties, engineering variables, and testing protocols that are crucial for the effective deployment of inflatable seals. Particular emphasis is placed on understanding the frictional characteristics of fabric materials, a key factor influencing seal performance.

Explore Our New Tool:

Cross Section Selector

Are you frustrated with poor product quality, long lead times or being unable to get your inflatable seals from your normal supplier? Provide us with information about what kind of seal you are looking for and we will match you with an existing Seal Master Corporation cross section or refer you to our engineering team for custom manufacturing.