Seal Master’s fabrication process delivers consistent pressure along entire surface for high volume duty cycles

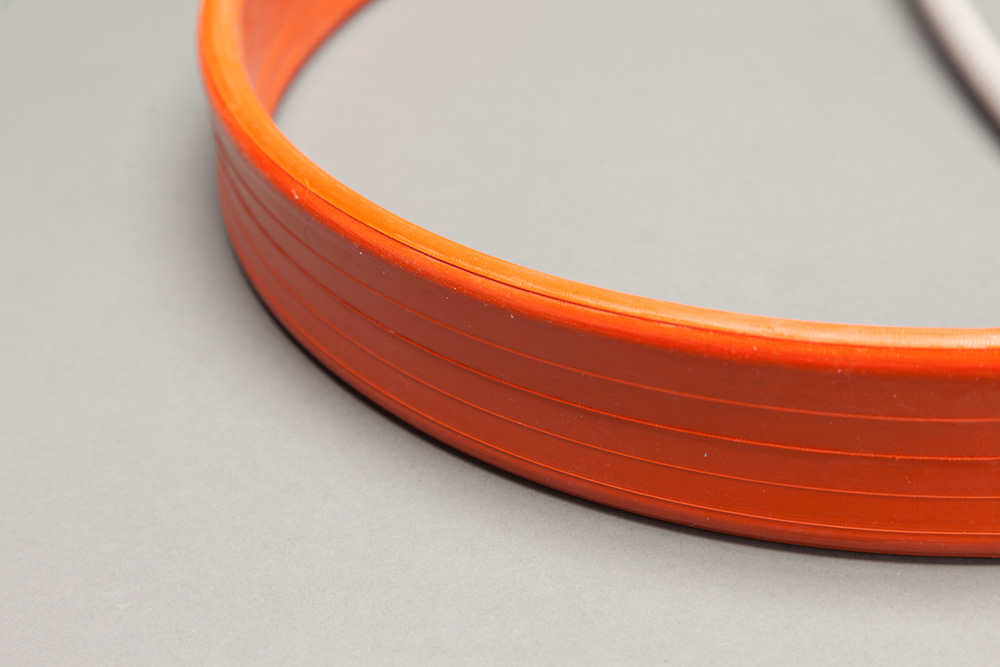

Fully-molded construction means that both high temperature and pressure are incorporated in the fabrication process to improve the rubber’s strength. This process improves the elastomeric properties of the material. The result is consistent and even inflation pressure along the entire striking surface. Greater structural integrity also brings longer product operation.

Our company designs and manufactures fully-molded rubber inflatable seals and bags (or bladders). Seal Master will recommend an elastomer to suit your specific application. Available elastomers include Butyl, Chloroprene (Neoprene), Epichlorohydrin, Ethylene Propylene, Fluorinated Hydrocarbon (Viton), Natural Rubber, Nitrile (Buna N), Polyurethane, Silicone, Styrene Butadiene, (Buna S). Products may also include reinforcing fabric such as DuPont’s Kevlar®, Dacron®, Nomex®, and Nylon.

Because we are involved in each step of the process, from early design to product fabrication and manufacturing, Seal Master is in perfect position to innovate for the best balance between performance and cost consideration.

And because we use quality materials and enforce strict internal QA/QC standards, we stand behind our work. Our fully-molded seals can endure even the most extreme environments.

Two problems with competitive products

Spliced seals start with an extrusion cured with heat but not under pressure. A seal made by “spot cure” uses heat and some pressure to join the ends together which leaves an area that does not expand as easily the rest of the seal. The problem: inconsistent pressure along the structure, and early product failure.

Seal Master’s fully-molded products have two primary benefits over the competition:

- greater structural integrity to deliver consistent inflation along the entire length of the seal

- longer cycle duties with zero faults

The Seal Master Difference

Seal Master has been designing and manufacturing custom engineered, hand built, fabric reinforced inflatable seals and manufactured rubber products since 1974. For more than forty years the company continues to earn the respect and business from all over the world. Recognized for its superior products, many of which are critical components in many facilities. Seal Master’s custom engineering has served heavy industrial, environmental, and high-tech organizations all over the world.

We are ready to get to work on your project!

Contact us today to get your Reinforced Inflatable Bags or Reinforced Inflatable Bladders designed and manufactured to your specific application.

Submit an email to us via our contact page, or better yet, send us a detailed request from our Design Assistance page. We look forward to creating with you!