Quality Assurance Program

At Seal Master, we take pride in our products and stand by their quality. Quality built, quality tested!

At Seal Master, we stand behind our American-made products, and we know that our customers rely on the reliability and durability that our fabric-reinforced inflatable seals are known for. We make sure that every product we send out is free from problems or defects. Each and every product that is shipped out is inspected a minimum of two times, by at least two separate Seal Master Quality Inspectors.

In addition to cosmetic defects, we also make sure that our products operate correctly. One of the things that makes Seal Master the industry leader in inflatable seals manufacturing is our mandatory and optional product inspections and tests.

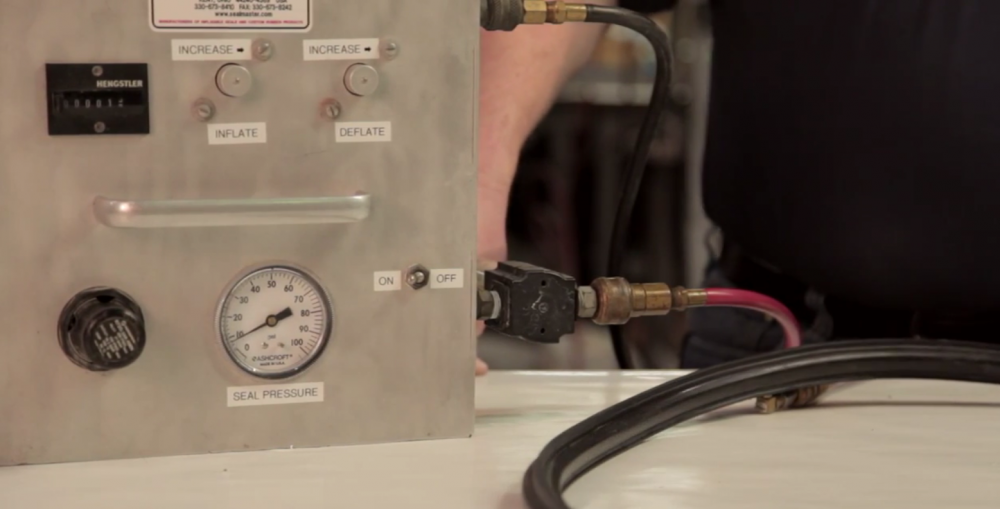

Mandatory Underwater Leak Test

Each Seal Master product must pass a mandatory underwater leak test inspection twice prior to shipment. Each part is inflated with a standard air pressure during these tests.

Optional Burst Test

A burst test is designed to document the product’s maximum operating pressure. This gives our designers and engineers data in order to assess how the product will perform in its operating environment. This is an optional test but can be performed upon request.

Optional Pressure Decay Test

Our customers can request an optional pressure decay test, which involves inflating the seal from 1-24 hours to ensure that the seal does not lose pressure over time.

Optional Product Cycle Test

Some customers request that we cycle-test their product, which is where an inflatable seal or bag is brought up to a desired air pressure and then opened, releasing pressure, for multiple cycles. The number of cycles varies and is usually dependent on the application the seal will be used for.